Common T Slot Sizes

- Metric T Slot Aluminum Profiles

- Connectors

- Fasteners

What is the right way to measure t-slots? My slots measure.625 (5/8) inch and the 't' portion measures 1.125' across. The most common type of aluminum fastener used to fasten parts together is the T-nut: just drop it into the T-slot and then twist it into a locked position. That is so much easier than welding! But where the real magic happens is in the versatility of our aluminum connectors.

- Accessories

- Frame to Floor

- Panel Accessories

- CarboSix Carbon Fiber

With T-Slot Aluminum, you get more value than you ever would with welded steel. Need flexibility? You've got it with t-slot aluminum. Need Versatility? Extruded aluminum has that too. Strong in the hot or the cold, corrosion resistant, extruded aluminum has everything you need to get a project done quickly and efficiently. No need to paint or weld unlike steel parts. Get whatever you need built fast and strong with our metric series profiles of extruded aluminum framing.

The T-slot Extruded Aluminum Advantage

For thousands of years humans have been fabricating useful, pleasing furnishings and other structures for the home and workplace out of an impressive range of materials, including straw, mud, stone, wood, brick, iron, steel, and other metals of various sorts. But it is only within the last hundred years or so that aluminum the most abundant metal in the Earth's crust has been utilized in an ever-increasing number of day-to-day applications. Partly this is because a cost-effective process for extracting aluminum from bauxite ore was not perfected until about 1920.

So there is one great advantage of employing aluminum for structural design purposes: it is plentiful. Its other advantageous properties include strength, lightness, formability, high ductility, and excellent corrosion-resistance. The innate utilitarian value of those properties is vastly magnified when the metal is formed into T-slot aluminum extrusions.

In a nutshell, T-slot aluminum forms the basis of a framing system for creating three-dimensional structural assemblies made with a variety of extruded and fabricated aluminum parts. With this system, each length of extruded aluminum contains one or more T-shaped indentations, or slots, into which various attachments (with ends also shaped like a 'T'?) conveniently fit and can slide up and down as needed. This allows you to interconnect other T-slotted aluminum parts into even the most complex configurations without having to clamp and weld them together as you would have to do with steel components.

Here are a few of the key advantages of adopting T-slot aluminum solutions to meet your structural design needs.

Strength

True, steel is harder and 'stronger.' But by the same token, aluminum is among the lightest of metals used for modern engineering purposes, with a molecular density one-third that of steel. As a result, it possesses a strength-to-weight ratio that is actually superior to that of steel . Contrary to what you might think, extruded aluminum is strong enough to handle most structural design and assembly applications.

Once you factor in the inconvenience of moving and positioning heavy pieces of steel not to mention the added labor cost of welding or riveting them together, drilling and tapping holes for mounting bolts, and then cleaning, prepping, priming, and painting the surface of the metal then T-slot aluminum becomes an increasingly attractive option if you are seeking cost-effective structural framing solutions.

Durability

If it's tough enough for trucks, military combat vehicles, and commercial airliners, then rest assured that aluminum is tough enough for more prosaic, everyday purposes. One key aspect of this durability is its resistance to rusting. Rust is to steel as rot is to wood. Unlike steel, for all intents and purposes aluminum doesn't rust at all. A microscopic layer of oxide (which is responsible for the silvery-gray color of anodized aluminum) naturally forms on the surface of the metal and prevents that from happening. You don't even have to prime and paint it in order to protect it! If any of your project's aluminum extrusions or other parts never rust, then you'll never have to replace them saving you money and down-time in the long run.

Versatility

Finally, one of the most important advantages to using T-slot aluminum extrusions and accessories is that, unlike permanently welded steel, the system is modular by design i.e., it is easily changeable. You can connect, position, and fasten together the aluminum profiles however you'd like, using the appropriate fasteners , connectors , and desired accessories . Later on, as needed, you can then adjust and rearrange them in any configuration you like.

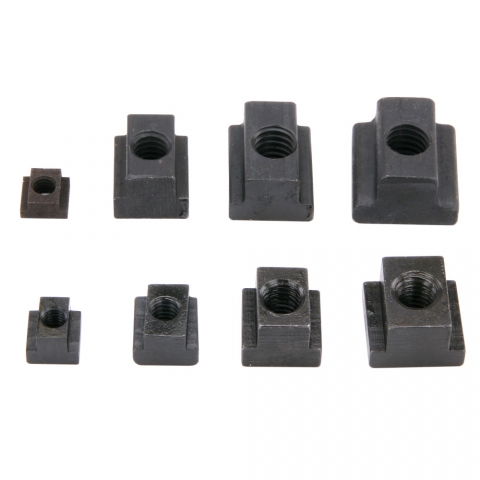

The most common type of aluminum fastener used to fasten parts together is the T-nut: just drop it into the T-slot and then twist it into a locked position. That is so much easier than welding!

But where the real magic happens is in the versatility of our aluminum connectors. Just a partial list would include:

- quick connectors

- T-connectors

- tilt connectors

- milling connectors

- bolt connectors

- cube connectors

- angle connectors

- slotted gussets

- corner brackets

Once you've put the finishing touches on the assembly with end caps, casters, cable blocks, machining jigs, tool hangers, cabinet siding, doors, or any of a number of other accessories that we carry, you're good to go!

For maximum versatility for both both our international and domestic customers, be aware that our T-slot aluminum extrusions come in both metric profiles and inch profiles .

From carts to aquarium stands , from shelves to enclosures , and from ergonomic workbenches to eye-catching signs , Framing Tech T-slot aluminum extrusion systems are designed, machined, and assembled for versatility—and they are built to last.

T-Slot Aluminum FAQs

What is T-slot Aluminum Extrusion?

T-slot aluminum extrusion is a structural fabrication material that utilizes an engineered cross-sectional profile that is both strong and versatile in its use.

Will T-slot Aluminum Extrusion corrode?

Our aluminum extrusion is non-corrosive. This is mostly due to the clear anodized finish that comes standard on all of our extrusion, but also due in part to aluminums natural ability to oxidize. The oxidation process creates a secondary layer of protection from corrosion, similar to how copper will patina.

Is T-slot Aluminum Extrusion considered a “Green” material?

Yes! Due to excellent recycling practices most of the aluminum ever produced is still in use today. In fact, aluminum is 100% recyclable and of the most common materials recycled aluminum is the ONLY material that is infinitely recyclable. It is also much lighter than glass and steel per cubic inch, and has a much smaller carbon footprint during fabrication, processing, and shipping.

Why choose aluminum extrusion over steel?

The main advantages are that aluminum extrusion is more versatile, modular, easier to work with, and costs less than steel. Building with aluminum extrusion is as simple as inserting a connector into the t-slot and tightening it into place with standard hand tools. No need to clamp, weld or paint aluminum extrusion. T-slot aluminum extrusion makes it easy to re-locate pieces or add onto your current structure at any time.

What is aluminum extrusion used for?

Currently, T-slot aluminum extrusion is widely used in automation, material handling, safety guarding, manufacturing and laboratory applications. However, many people are adopting t-slot aluminum extrusion for use in a wide variety of projects. Some have even built their own machines such as 3D Printers and CNC machines using our aluminum extrusion.

What is a T-slot, and how do I use it?

A T-slot is what we call the channel that runs the length of our aluminum extrusion shapes. The T-slots are designed to a specific depth and width depending on the material. The T-slot is used mostly for mounting and fastening a wide variety of accessories and panels to the aluminum extrusion. Often, panels will be inserted into the T-slot to quickly create a wall or enclosure.

This information applies to the American Steel Industry.

Holes and Slots

Standard Holes

Standard hole sizes for bolts are made 1/16-in. larger in diameter than the nominal size of the fastener body. This provides a certain amount of play in the holes, which compensates for small misalignment’s in hole location or assembly, and aids in the shop and field entry of fasteners. In the absence of approval by the engineer for use of other hole types, standard holes shall be used in high strength bolted connections.

Although most holes for high-strength bolts are made 1/16-in. larger in diameter than the bolt body, certain conditions encountered in field erection require greater adjustment than this clearance can provide and approval from the engineer is required.

The maximum sizes of holes for bolts are given in the table below, except that larger holes, required for tolerance on location of anchor bolts in concrete foundations, are permitted in column base details.

Standard holes shall be provided in member-to-member connections, unless oversized, short-slotted or long-slotted holes in bolted connections are approved by the designer. Finger shims up to 1/4-in. may be introduced into slip-critical connections designed on the basis of standard holes without reducing the allowable shear stress of the fastener.

Oversize and Slotted Holes

When approved by the engineer, oversize, short slotted holes or long slotted holes may be used subject to the following joint detail requirements:

(1) Oversize holes may be used in any or all plies of connections in which the allowable slip resistance of the connection is greater than the applied load. Oversized holes shall not be used in bearing-type connections. Hardened washers shall be installed over oversized holes in an outer ply.

(2) Short slotted holes may be used in any or all plies of connections designed on the basis of allowable stress on the fasteners provided the load is applied approximately normal (between 80 and 100 degrees) to the axis of the slot. Short slotted holes may be used without regard for the direction of applied load in any or all plies of connections in which the allowable slip resistance is greater than the applied force. Washers shall be installed over short-slotted holes in an outer ply; when high strength bolts are used, such washers shall be hardened.

Common T Slot Sizes Chart

(3) Long slotted holes may be used in one of the connected parts at any individual faying surface in connections designed on the basis of allowable stress on the fasteners provided the load is applied approximately normal (between 80 and 100 degrees) to the axis of the slot. Long slotted holes may be used in one of the connected parts at any individual faying surface without regard for the direction of applied load on connections in which the allowable slip resistance is greater than the applied force. Where long-slotted holes are used in an outer ply, plate washers or a continuous bar with standard holes, having a size sufficient to completely cover the slot after installation, shall be provided. In high-strength bolted connections, such plate washers or continuous bars shall not be less than 5/16-in. thick and shall be of structural grade material, but not be hardened. If hardened washers are required for use of high-strength bolts, the hardened washers shall be placed over the outer surface of the plate washer or bar.

(4) Fully inserted finger shims between the faying surfaces of load transmitting elements of connections are not to be considered a long slot element of a connection.

Nominal Hole Dimensions

Anchor Bolt Holes

Hole sizes for steel-to-steel structural connections are not the same as hole sizes for steel-to-concrete anchorage applications. In the case of steel-to-steel connections, the parts are made in a shop under good quality control, so standard holes (bolt diameter plus 1/16″), oversized holes (bolt diameter plus 3/16″), and short and long-slotted holes can be used quite successfully. However, the field placement of anchorage devices has long been subject to more permissive tolerances (and often, inaccuracies that exceed those tolerances anyway and may require consideration by the structural Engineer of Record).

AISC published Steel Design Guide Series 1, Column Base Plates back in the early 1990s. At that time, it was recognized that the quality of foundation work was getting worse and worse. To allow the erector (and designer) greater latitude when possible, the permissible hole sizes in base plates were increased. These same larger hole sizes were included in the 2nd ed. LRFD Manual. The values there are maximums, not a required size. Smaller holes can be used if desired. Plate washers are generally required with these holes because ASTM F436 washers can collapse into the larger-sized holes, even under erection loads.

The larger hole sizes are primarily intended for the majority of base plates that transfer only axial compression from the column into the foundation. The anchor rods don’t usually do much after erection in that case.

To allow for misplaced bolts, holes in base plates are oversized. The AISC Manual of Steel Construction recommends the following oversized hole diameters for each bolt diameter:

Anchor Bolt Hole Dimensions

AISC, Steel Design Guide Series 1, Column Base Plates, suggests that using oversize holes meeting these criteria may still not accommodate field variations in anchor bolt placement and suggests adding 1/4 in. to the hole diameter listed. The guide recommends using a heavy plate washer over the holes. The AISC Structural Steel Educational Council cites the following example: “If bolts are misplaced up to 1/2 inch, the oversized base plate holes normally allow the base plate and column to be placed near or on the column line. If the bolts are misplaced by more than 1/2 inch, then corrective work is required.”

Common T Slot Sizes Diagram

Based on AISC oversize holes, the AISC Structural Steel Educational Council recommendations, and concrete contractor anchor-bolt placement techniques, ASCC (American Society of Concrete Contractors) concrete contractors recommend the following tolerance for each bolt location:

Common T Slot Sizes Explained

- 3/4-in. and 7/8-in. diameter bolts: ±1/4 in.

- 1-in., 1-1/4-in., and 1-1/2-in. diameter bolts: ±3/8 in.

- 1-3/4-in., 2-in., and 2-1/2-in. diameter bolts: ±1/2 in.

End of article.